OEM (original equipment manufacturer) and ODM (original design manufacture) are two well-known terms in the manufacturing sector. Mostly people got confused with the both of these terms while going through the manufacturing terminologies. There are various OEM/ODM suppliers in the market like gvepower.com who have been manufacturing the OEM and ODM products and supplying it to the market.

How OEM and ODM Products Are Different?

In this article we will be precisely talking about the core differences between both from which most of us are unaware. People are usually mixed-up with the definition and services provided by the both of the manufacturers.

What is OEM?

As said above, OEM stands for original equipment manufacturer. OEM manufacturers are those companies which are supposed to manufacture the products based on the given product design and specifications that are provided by the client. Client is responsible for all the market research and R&D for their product whereas the OEM is responsible to manufacture the product as per the given requirements.

For examples, Apple and Samsung spend millions of dollars on their product line but gets it manufactured by any of the OEM like Foxconn. In this case, the vendor Foxconn is not responsible for the product design rather it is only responsible for manufacturing the product.

What is ODM?

ODMs are the original design manufacturers and the companies that are hired for creating new product design and specifications based on the product idea provided by the client. ODMs may also manufacture the product they have designed and the client gets the final product along with its own branding and name.

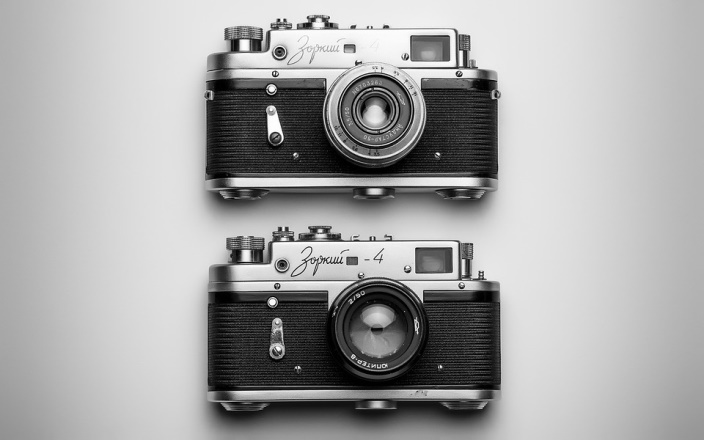

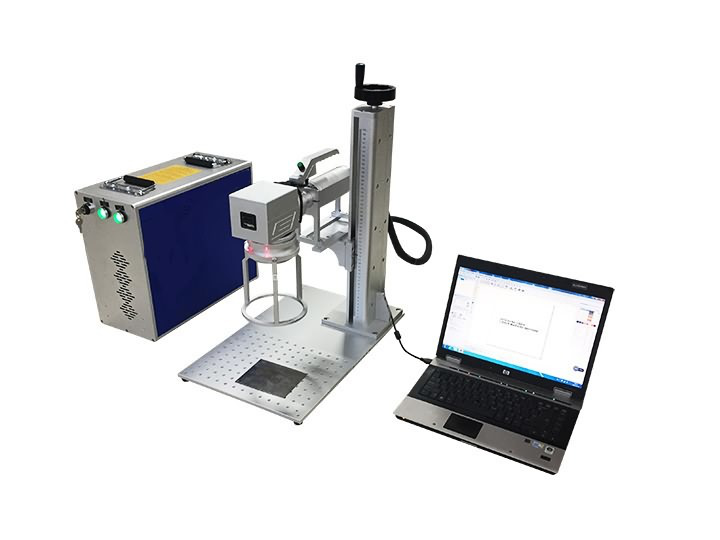

OEM and ODM

There are various Chinese technology brands that get their products designed from any ODM company and sells it with their own name and branding in the open market. Some of the services that usually an original design manufacturer will provide are as follows:-

- Outsourced product development

- Product manufacturing

- Product designing

- Product life cycle service etc.

OEM and ODM

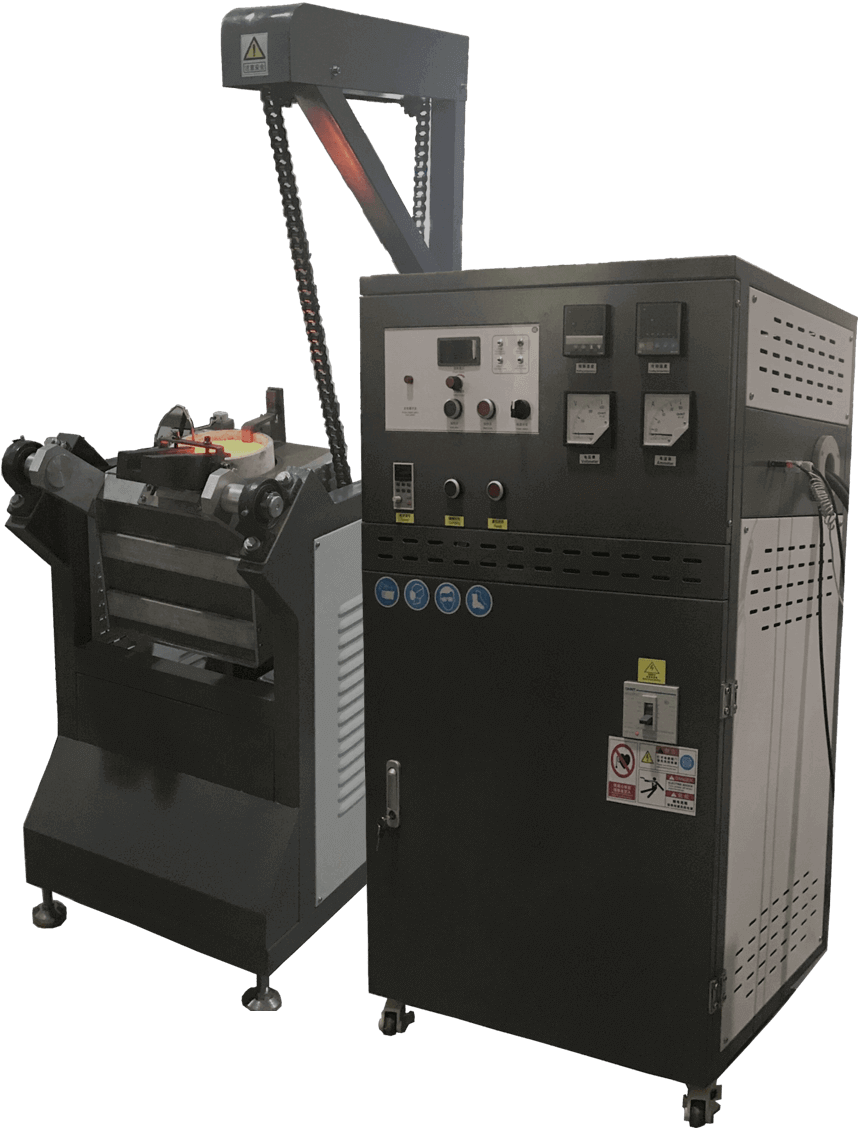

What Industries Are Being Served By OEM and ODM?

Both of the manufacturers are not limited to just technology sector only rather they have been providing there services for the companies who are dealing in consumer electronics and in the engineering sector as well. OEM/OEM is more common in technology industry because this sector is more design intensive and progression is being made in a very quick manner.

Original design manufacturers and original equipment manufacturers are also providing it seamless services in the industries like fashion, footwear, personal grooming, home appliances, electronics etc.

When you are working with an OEM company you have to only provide them with the secret product design you have come up after intense R&D and the OEM will get the product developed whereas the OEM will get the product specifications and design by themselves and you will be provided with the end product with your branding over it, and that’s what you have paid them for.

After reading the whole write-up you should now be clear with the differences between original equipment manufacturer (OEM) and the original design manufacturer (ODM) that how they are different with each other and how they have been provide their services to the industries in the market we have talked about!