There are several gearboxes available on the market. That is why it is important to match the type of box with the motor, load, in addition to the drive. When your machine requires a drive and motor, then the type of gearbox is essential for accurate motion. Precision gearbox fits the description for various applications.

High-precision gearboxes are a perfect choice for different applications that require reliability coupled with accuracy. Planetary gearboxes have relatively low backlash ratings which range between 1-8 minutes.

When sized appropriately, these precision gears can provide a service life of more than 22,000 hours with no maintenance. Our planetary gears provide quiet operations as compared to our counterparts.

Other than that, precision gearboxes are often machined to unique tolerances (high)- think clockmaker and not a blacksmith since they provide power densities which translate to a small package size coupled with an efficiency of up to 80 percent and above.

Our servo motor planetary gearbox control comes with a rotary arm in a machine that dispenses products, to give accurate positioning as needed by the demanding application.

So Why Should You Use A Precision Gearbox?

This gearbox has the ability to drive loads directly into the dispensing machine without the demand to feed for a gearbox. However, in several applications, this is a pro especially if you can use a gearbox between the load and then motor of the device. One primary reason why you should use a gearbox is the torque application.

The precision gearbox allows its designers to use smaller servo systems which consume lesser energy. Rather than purchasing large servo drives coupled with motors, the designer may use relatively smaller components to save space and money.

The output torque can increase in direct proportion to the actual gear ration. It can also top the speed of the shaft. If the application can withstand the speed the lowered speed, then a small servosystem may supply high torque.

And for high performance, the ones with a dynamic system response or a lower overshoot, for instance, needs to be as low and as practical as possible.

A precision gearbox will reduce the total reflected inertia of the reduction ratio. For example, using a 32.1 gearbox reduces the total load of the inertia by 625, which is a significant improvement altogether. In different unique cases, precision gearboxes resolve issues pertaining to mechanical fit.

For instance, if when mounting the motor interferes with a mechanical component, then a gearbox with a right angle can easily resolve the problem.

Every gearbox uses a different power transmission method. In servo applications, precision gearboxes are suitable. Worm gears, on the other hand, utilize a warm screw gear in converting a large transverse gear.

Final Thoughts

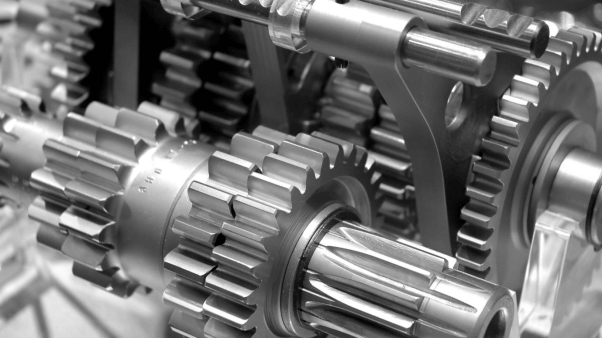

Planetary precision gearboxes were named for how they look like a simple solar system. They come with a ring gear and planet gears coupled with a sun gear. In many cases, the ring gear is fixed and a huge component of the outer casing of the gearbox. The cutaway image of the two-stage precision gearbox indicates the side-clamping collar, particularly for the servomotor shaft.