One of the commonly used methods of manufacturing has got to be injection molding. While there are other processes in the market like CNC machine processing, prototype injection molding continues to be one of the leading processes in production. If you have no idea whether this is the best option for you, take your time and read through this article. You will get to see why injection molding is preferred and how it could benefit your business.

What is injection molding?

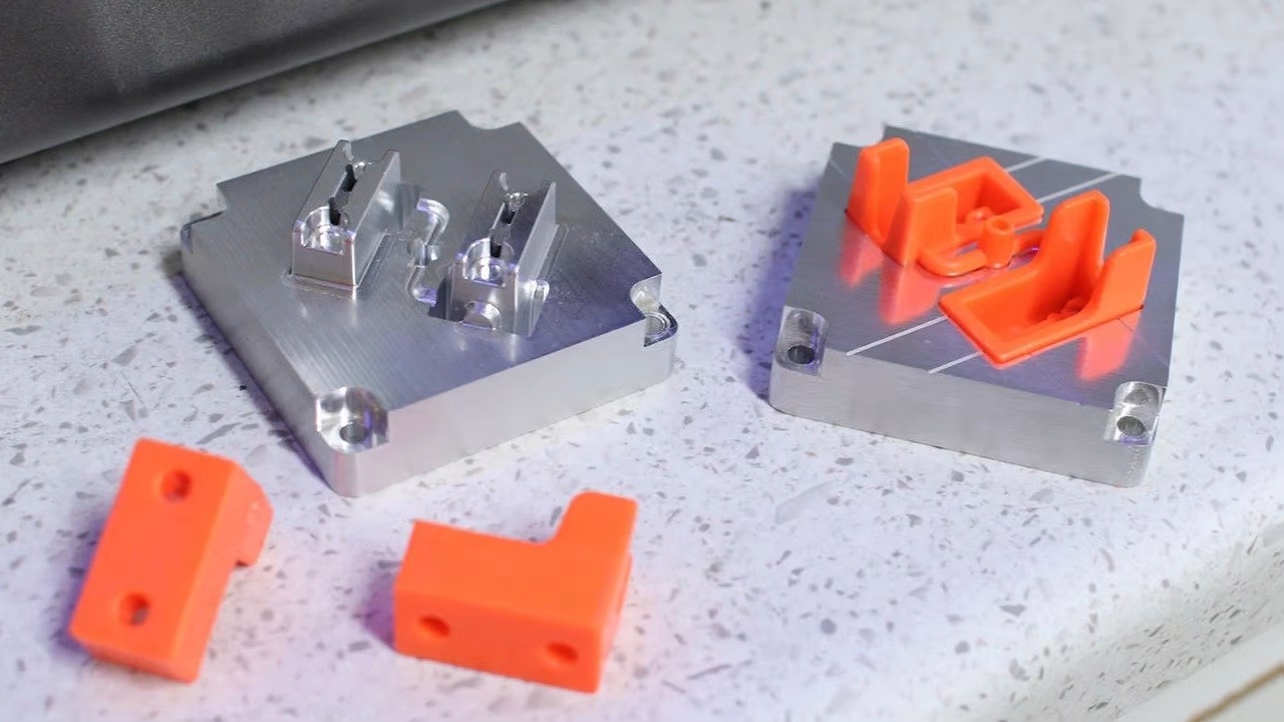

Simply put, injection molding manufacturing allows you to create parts by injecting liquid-like raw material into a mold. The liquids used are mostly polymers, although there are situations where glass and metal are used. The process begins by heating pellets into a liquid, and then the liquid gets forced into the mold design. Once the liquid solidifies, remover pins are used to get it out of the molds.

Uses of ejection molding

Even though injection molding is used in most manufacturing plants. Many people do not know about this and might get confused about whether it is the right manufacturing process for their products. Here are some of the areas where products of injection molding are used:

- Wire spools

- Automotive parts

- Toys

- Bottle caps

- Some musical instruments.

With all the uses listed, it is no surprise that injection molding has gained popularity over the past years.

Benefits of using injection molding

There are various perks of using injection molding that make it a favorite for many people. Knowing about it will help you make the right choice when it comes to choosing molding parts.

1. It is fully automated

One of the biggest perks of injection molding is, it is fully automated. It allows for one to produce more pieces in a day that look the same. One does not have to worry about their pieces looking different when they use injection molding.

2. Designs intricate parts

Another reason injection molding is a great process is that it can be used to create intricate parts as long as the mold has been correctly designed. You can get some interesting patterns on your products. It comes in handy, especially when one wants their products being made to be branded.

3. It produces things en masse

If you want products to be produced on a large scale, injection molding is the best option. You get to make almost 1000 pieces per hour which can be great if you are looking for a mass production method.

4. Has little waste

Since injection molding is an additive process, you get to reduce the losses you make with every piece. Compared with CNC machining, which chips away at the material, there is every little loss with this process. You can be sure that you will use up as little material as possible to get the product you need. It makes the entire process bring in more profits than any other process.

Conclusion

Injection molding is one of the embraced methods of production around the world. Knowing about this will help you appreciate it more and make a conscious decision on your manufacturing process.