As the manufacturing business grows across the world and becomes more complex, a lot of firms are now exploring the benefits of outsourcing various manufacturing processes. Famously known as contract manufacturing, the business involves the outsourcing of a third party to undertake some functions, which the manufacturer may not be able to do because of the lack of time, equipment, space or expertise. Hiring a contract manufacturing company such as Inno Manufacturing will give you many advantages as a manufacturer. Such benefits are discussed below.

Benefits of Working with a Contract Manufacturing Company

The Reduction of Costs

The reduction in operating costs is one of the most crucial benefits of outsourcing a manufacturing company. A company which offer contract manufacturing services can purchase their materials in bulk hence can perform their work at low costs. Such cost savings can be passed over to your customers enabling you to gain a competitive edge in the marketplace.

Access to Specialized Expertise

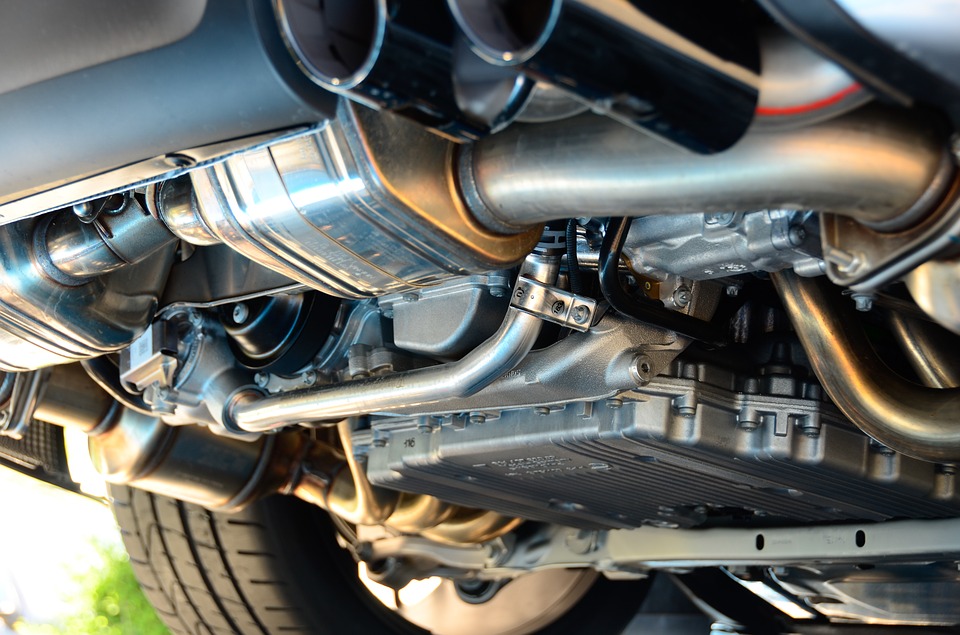

With the current evolution in manufacturing technology, it is possible that some small companies may not be in a position to keep pace. Outsourcing for manufacturing services allows you to leverage on the latest technology for your business. You will always be in a place to offer better services to your clients without having to worry about expensive technology upgrades.

Contract Manufacturing Company

Increases Your Capacity

Every manufacturer would want to spike up their businesses. That is with an aim to meet the growing demand for their products. Outsourcing some aspects for your operations on temporary or permanent bases could prevent you from lagging in your business. Choosing a contract manufacturer who understands what you need can increase your production. The best contract manufacturing firms will provide you with a quick turnaround that goes beyond your expectation as a manufacturer.

You Get Specialized Manufacturing Services

The best contract manufacturing firms will be able to provide you with the best-specialized manufacturing services. Great companies comprise have automated machines and the most potent mechanical machines which can be tuned to produce goods which best fit the needs of your clients or customers. A custom manufacturing contractor will be able to give the highest quality since they work with you in every step to ensure that the specifications of the products are met.

Quality Control and Assurance

Contract Manufacturing Company such as Inno Manufacturing ensures strict quality control measures which conform to the federal and state requirements. Contract manufacturing firms have comprehensive knowledge in the production of quality products for various industries. Testing all the products before shipment remains to be their value-added services.

Contract Manufacturing Company

Conclusion

It is essential to be careful when choosing the right contract manufacturer. That is because not every company is able to provide you with quality custom manufacturing services as you desire. Working with an inexperienced contract manufacturer may lead you into unexpected losses at the end. Find a reputable custom contract manufacturer and reduce such unforeseen risks.

5.Lockheed Constellation. The Connie is known for being the first pressurized airliner in widespread use. Built between 1943 and 1958, the Constellation ushered in an era of affordable and comfortable air travel.

5.Lockheed Constellation. The Connie is known for being the first pressurized airliner in widespread use. Built between 1943 and 1958, the Constellation ushered in an era of affordable and comfortable air travel.