The online marketplace has radically transformed shopping. As opposed to traditional brick-and-mortar retail shops, purchasing goods online is convenient and easy. In most cases, your product is shipped and delivered to your doorstep. However, shopping online lacks the personal touch associated with traditional retail shops.

The online marketplace has radically transformed shopping. As opposed to traditional brick-and-mortar retail shops, purchasing goods online is convenient and easy. In most cases, your product is shipped and delivered to your doorstep. However, shopping online lacks the personal touch associated with traditional retail shops.

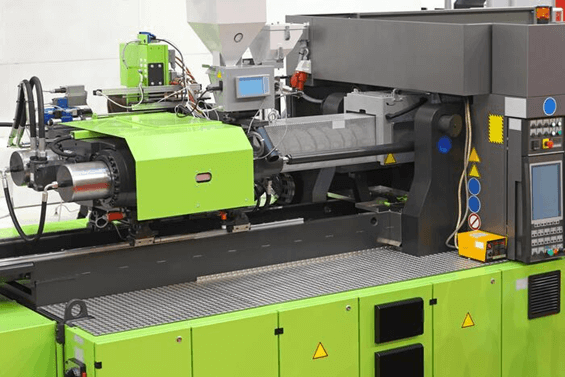

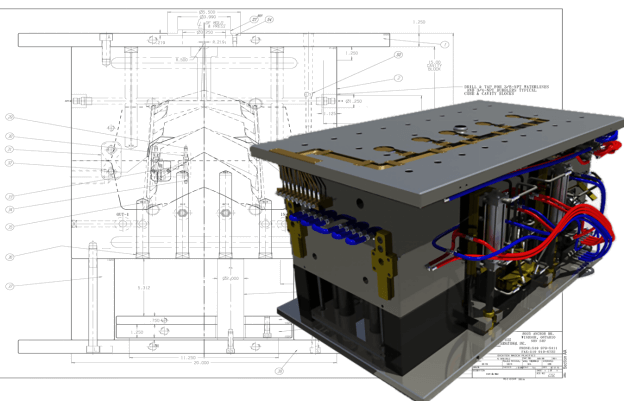

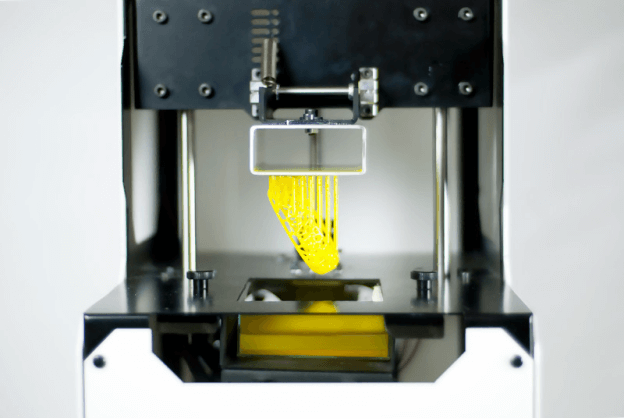

You also lack the opportunity to test the goods first before making the purchase. Therefore, you may end up with the wrong size plastic injection mold or damaged one. For more useful information on plastic injection molds before ordering one online, check our blog post on injection mold.

Consider the following factors when shopping online for plastic injection molds:

- The credibility of the retailer: One of the best ways to avoid ending up with a faulty plastic injection mold machine or losing your money to online fractures is establishing the credibility of the e-commerce retailer. In this age of the Internet, online platforms offer some of the best and easy ways to carry out the assessment.

Visit the customer relation rating sites and the company’s website and go through the company’s profile and ratings. Customer reviews can also tell you a lot about a company. Send an email to the company if possible and ask for any details that you may need before making the purchase. Don’t ignore any red flags you notice or your intuition.

- Your molding needs:When shopping for molds, always understand what you need first before rushing online to go through the large product catalogs online. Understand the cooling system, tier bar spacing, press size, tonnage, and shot size of the mold you need. All these factors will determine the price of the plastic injection mold, the size and quality of the final product, and potentially, the clients you will attract.

Always be intentional when it comes to understanding your molding needs. Go through your inventory and confirm what gaps in production you need to fill. Sometimes the customer feedbacks or orders may give you a pattern of what you lack.

- Budget:Whether you are shopping online or at your local walk-in store, always work with a budget. Avoid impulse buying by searching for prices on the plastic injection mold of your choice online. Have the selected e-commerce retailers mail their prices if they are available online. Getting different quotes for various vendors will ensure that you get a broader sense of the pricing trends.

- Additional costs and discounts:Getting the best deal on a plastic injection mold online sometimes requires visiting several websites and checking on their deals and offers. Check whether your preferred online retailer is offering any special discounts on their product. Before making the purchase, always confirm whether the price is inclusive of the shipping cost.

Take-Home

Shopping online for a plastic injection mold requires careful consideration of additional costs and understanding your molding needs. Avoid making any purchase without making a budget and checking the credibility of a retailer. Failure to carry out a background may leave you with a poor quality yet expensive mold with no return policy.