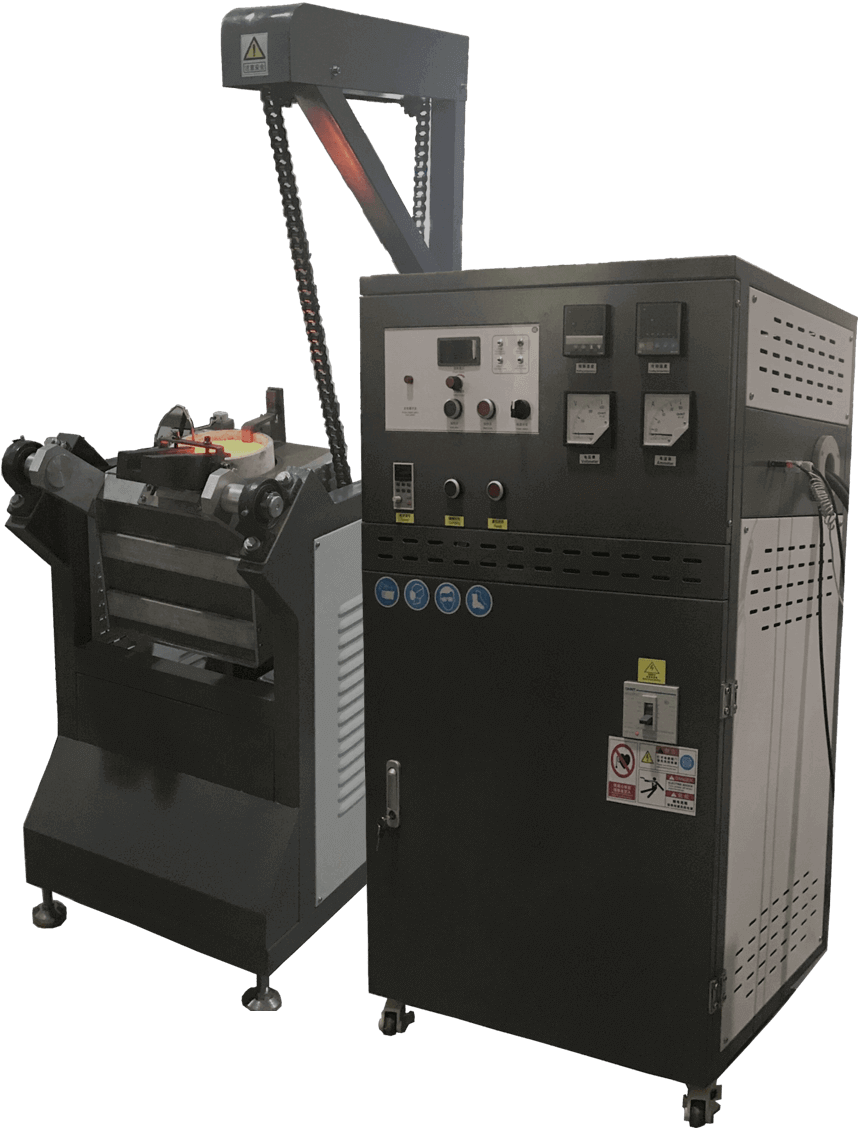

Gold production has come a long way from using propane stoves in extremely hot surroundings to clean, easy one-step process. However, to make the output easy, investing in a gold melting machine is imperative. Nonetheless, with many machines of the same purpose in the market, it can be challenging choosing a gold melting furnace that meets your needs. Despite the challenges of selecting the correct machinery, below are reasons why you need to invest in a furnace for personal or business use.

- A Gold Melting Furnace Has Robust Safety Features

For centuries, the smelting of gold has been regarded as a hazardous activity. With gold melting point relatively high, risks of fire hazard and burns are always there. When investing in a gold melting furnace, these hazards are minimal as it has a robust trigger warning system. For this reason, avoidance of potentially dangerous conditions are highlighted allowing you to maximize production hence increasing profits at low risks.

- A Gold Melting Furnace Has Zero Combustion

In smelting of precious metals, large amounts of carbon dioxide pollutions have always been a by-product. The pollution can be attributed to old fashion combustion of oxygen with fuels. Investing in an up to date gold melting kit limits environmental pollution through avoidance of using carbon-based effluents as a heat source hence avoids carbon dioxide pollution.

- Get Lower Power Consumption With A Gold Melting Furnace

Unlike old fashioned methods that used coal and wood as a source of heat, metal melting furnace uses electricity as a power source. The use of electricity enables smelting of metals at high-efficiency limiting of guesswork on whether the whole metal has been dissolved or not. What’s more, the use of the furnace drastically reduces the amount of period needed as in just mere minutes smelting is done. The result is a sharp contrast from traditional methods that used hours and relied on intensive labour to refill the power source.

- Assured Of Low Precious Metal Waste With A Gold Melting Furnace

With no spillovers and no open fire source, smelting of metals is done in a clean and practical matter. Efficient smelting translates to lowered incidences of precious metal loss. Ideally, with gold melting equipment, the use of cubicles is integrated into the design of the furnace system. As expected, the self-contained design allows for maximum precious metal recovery hence lowered waste.

- A Gold Melting Furnace Offers Easy Maintenance

Finally, the use of a melting furnace for gold production offers an easy maintenance option. With a removable cubicle, easy access is granted, and thus separation and cleaning can be done in a matter of minutes. Also, a built-in water feature allows pump connection that prevents overheating of the core system. With the furnace easily separated in different elements, replacement in case of damage is done quickly without worry or a need to replace the whole induction furnace.

Conclusion

Overall, when using a gold melting machine, you are assured of high-quality production of the precious metal. What’s more, you will no longer the constant support of technicians as operations of the gold melting furnace is sleek and manageable. With such great benefits, you cannot afford to not invest in an induction furnace for home or business use.