The confusion between Fused deposition modeling (FDM) and Fused Filament Fabrication has been on for a while now.

People keep wondering if they are the same. Some say they are, but others disagree and say they are different. The only way to find the answer is to look at the details.

In matters like this, it is always best to go back in time to see where each of these organizations started, to know how they have progressed over the years, their similarities, and their differences.

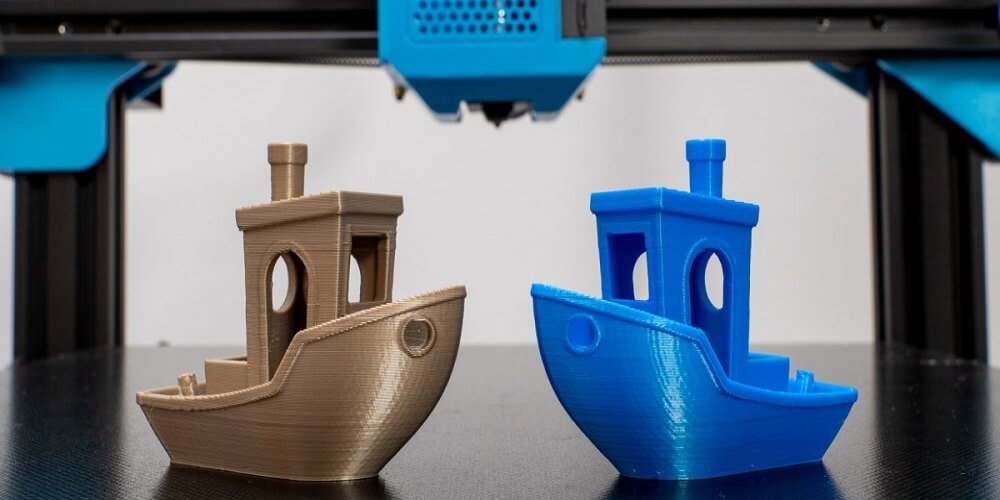

Putting the working principle of both processes before all is a good way to determine the differences and similarities. It will also compare the quality of their products.

Fused Deposition Modeling (FDM)

The FDM belongs to Stratasys, Ltd. Stratasys patented this technology in 1989. The well-known FDM machine a nozzle assembly, a table or built-platform, and a material filament.

when the filament enters the extruder, the extruder heats it with temperatures reaching 320 degrees Celsius. until it melts.

The filament then comes out through the nozzle and is carefully and selectively layered on the build platform.

The whole process of heating and melting and layering through a nozzle is isolated from the ambient environment.

The 3D printing process is built to maintain the temperature of the thermoplastic material that is used to print out 3D designs.

The temperature maintenance is done in order not to cause any structural damage that can result from sudden cooling damage to the design.

Fused Filament Fabrication (FFF)

When the FDM patent expired in 2009, a group came up to start manufacturing their version of 3D printers that FDM previously had.

This group called their equipment the Fused Filament Fabrication.

The purpose of the group that came up with FFF was to enable complex products to be manufactured without any industrial infrastructure set up.

They wanted people to be able to create complex components without big manufacturing bodies getting involved and using their industrial machinery to further it.

The FFF made a few changes in the design of their machine. The FDM used the process of heating the whole print chamber. The FFF did away with that part of the machine to save cost.

This meant that in the FFF, the filament goes through a hot extruder, then through an ambient environment, and then to a cold table.

The sequence of a hot to cold to hot pattern caused residual stresses in the model that was printed.

Conclusion

Back to the question. Are FDM and FFF the same technology? Well, yes. But that does not mean that they are the same thing.

They are both very similar but maintain some differences. Even though the FFF and FDM have the same architectural processes, the major difference is the output quality.

There is an obvious difference in the quality of their products. This is a result of the heating sequence in the different printers.

The FDMs heating sequence is a hot-hot-hot medium while the heating sequence of FFF is a hot-cold-hot medium.