Lip balm packaging is more than merely holding a product in the competitive beauty industry; however, it conveys the value of the quality, brand image, and consumer experience. The construction of a lip balm tube should create a fine balance between the look and functionality. This is attained at UKPACK, a lip balm tube manufacturer, by a well-considered design philosophy that blends aesthetic appeal with functionality. The design of the individual lip balm tubes is efficient in delivering a better user experience and reflecting the unique personality and brand promise of the company.

Aesthetic Appeal

Display helps attract customers and build brand awareness. UKPACK also understands that the customers would get their first glimpse of the product in its packaging design. Therefore, the company is geared towards producing lip balm tubes that are not only aesthetically pleasing but also in line with existing beauty sector trends. The brands can choose between a wide variety of colors, finishes, and shapes, which fit their market niche. The light pastel ones are used to talk about soft skincare, and the metallic colors convey luxury and innovation. UKPACK offers surface finishes, such as matte, glossy, gradient spray, soft-touch, and pearl-effect finishes, which enable brands to express classiness, freshness, or minimalism. \

Convenience and Comfort to the User

A tube of lip balm should be attractive and should also work perfectly well in day-to-day life. UKPACK has focused on ergonomic and practicality in its design in order to provide a pleasant and easy experience. The broad range of applicators available in the company, such as slanted tips, metal rollers, soft silicone heads, and rounded domes, serves the expectations of different lip care formulas and consumer needs.

An example would be metal applicators and soft silicone tips, which would provide a cooling experience and should be used with moisturizing and tinted lip balms. The tube will be organized with an appropriate size, style of the cap, and thickness of the material to secure a tight closure and selective dispensing to ensure that the product is easy to apply and hygienic. The design method employed by UKPACK is such that functionality does not interfere with the elegance.

Material Innovation

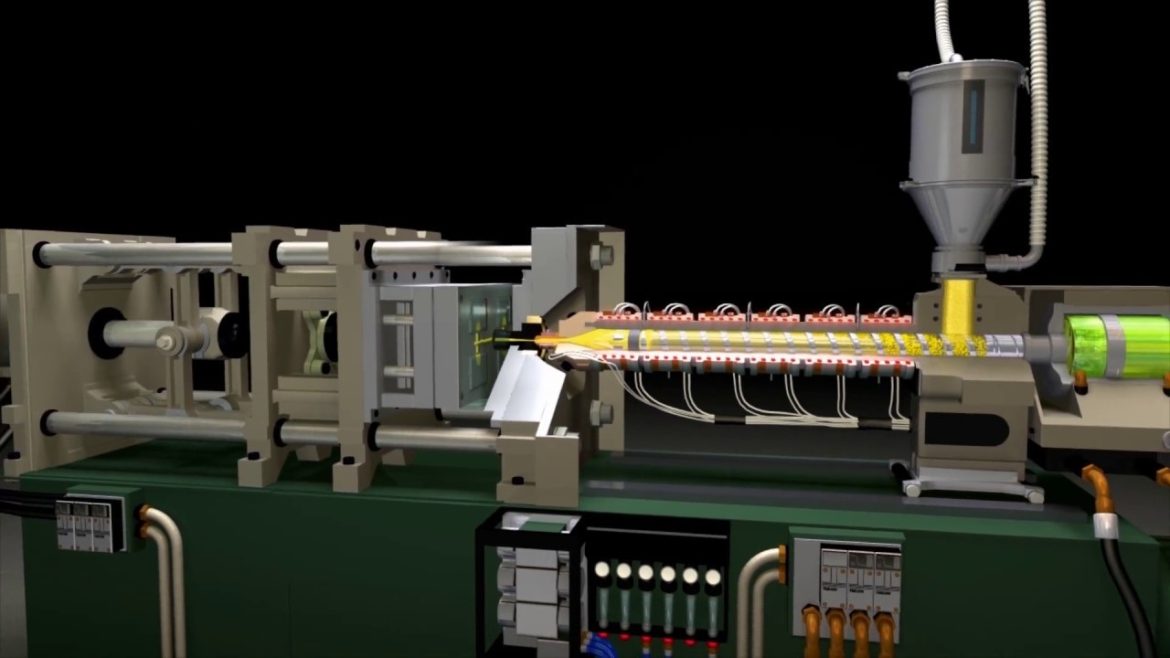

Consumers today are more attracted to the packaging that seems expensive but is in line with environmentally friendly ideas. The UKPACK is the first to implement this change and apply high-quality and sustainable materials like PE, PP, PETG, and PCR (Post-Consumer Recycled) plastics. Such materials are durable, flexible, and recyclable – and as such, the materials are appropriate to brands that appreciate performance and environmental sustainability.

The designs of the packages of the company simplify recycling and are made of the same type of plastic throughout the tube. The innovation has less impact on the environment but does not affect structural integrity and visual consistency. UKPACK assists brands in achieving global sustainability with design aesthetics and functionality without compromising on the material choice.

Represents Brand Personality

The advantage of UKPACK is in its capacity to offer fully personalized lip balm packaging, which reflects a specific tale of the brand. All the design elements, such as tube shape and size, finish, and decoration, can be customized.

The company has silk screen printing, hot stamping, digital UV printing, and labeling that assist brands to present their logos and artwork in clear and accurate ways. Minimalist designs are appropriate for clean beauty and natural product lines, whereas asymmetrical printed colors help to boost playful or youth brands. This design flexibility enables companies to design lip balm packaging that appeals to their audience without having to change the visual representation of the product across their product line.

Balance Between Form and Function

The design idea of UKPACK is centered around one thing: perfection of beauty and practicality. An excellent lip balm tube ought not only to appeal to the eye but also provide a smooth application. All the curves, applicators, and finishes have been designed to satisfy the aesthetics and functionality requirements.

In the case of beauty brands, this equilibrium can be seen in the form of packaging, which can lead to increased customer satisfaction, customer loyalty, and brand positioning. The combined nature of UKPACK design means that all the design elements have two functions: to impress the eye and provide performance.

Conclusion

The packaging design is as important as the product in the current market of beauty products. Lip balm tubes of UKPACK are the personification of the beauty and functionality that enable brands to take their lip care business to the next level with innovative, customizable, and sustainable packaging. The integration of creative design skills with production and sustainable materials enables UKPACK to help brands produce packages that are not only beautiful and convenient but also in line with current consumer demands in China and different countries.