Injection molding is a versatile manufacturing process used to create a wide range of plastic parts and components. Whether it’s producing intricate medical devices or everyday consumer products, understanding the injection molding process is crucial. In this step-by-step guide, we’ll take you through the key stages of injection molding, from concept to finished product. Check out the reliable injection molding services company by clicking the given link: https://www.kemalmfg.com/capabilities/injection-molding/

Step 1: Designing the Mold

The injection molding process begins with the design of the mold, which is the inverse of the desired part. Skilled mold designers use CAD software to create detailed 3D models of the mold cavity. This step involves determining the part’s shape, dimensions, and features, as well as considering factors like material selection, draft angles, and gating locations.

Step 2: Tooling and Mold Construction

Once the mold design is finalized, the tooling and mold construction phase begins. Skilled mold makers use precision machining techniques to create the mold’s core and cavity. This process demands exceptional accuracy, as even minor imperfections can affect the final part’s quality. The mold may consist of multiple components, such as cores, cavities, and slides, to accommodate complex part geometries.

Step 3: Material Selection

Selecting the right material for the injection molding process is crucial. The chosen material should align with the part’s intended use, as well as its mechanical, chemical, and aesthetic requirements. Common materials include thermoplastics like ABS, PP, and PC, as well as thermosetting plastics like phenolic and epoxy.

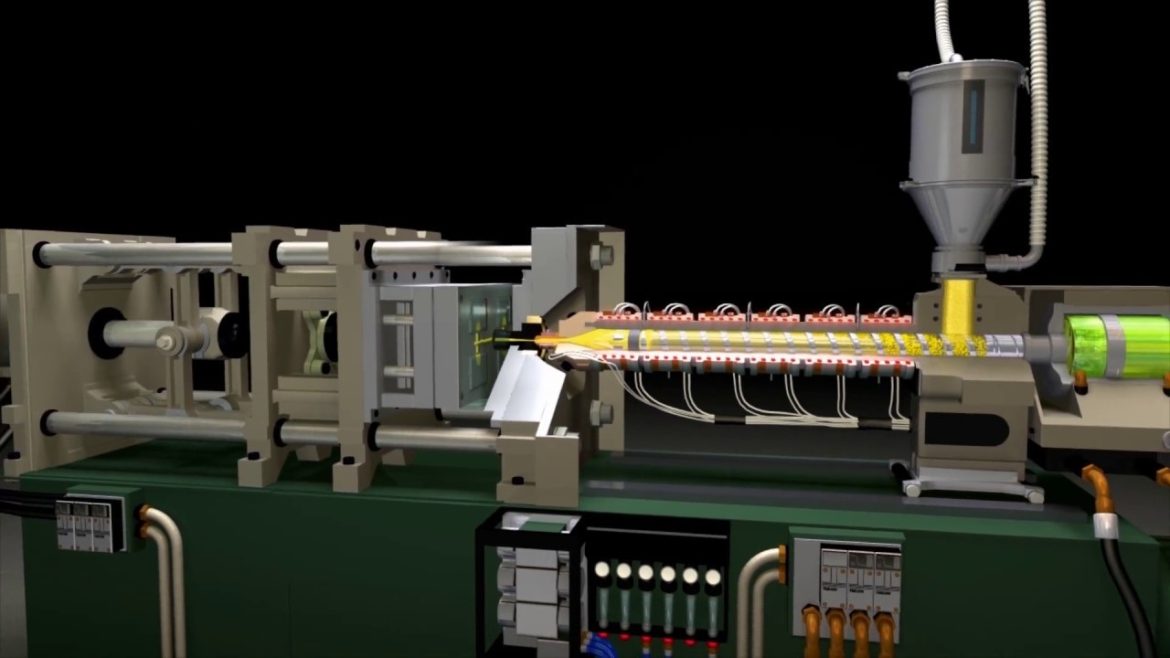

Step 4: Melting and Injection

With the mold in place, the selected plastic material is heated to its melting point in the injection molding machine’s barrel. Once molten, the material is injected into the mold cavity under high pressure. This injection phase ensures that the material fills all the nooks and crannies of the mold to create a precise replica of the desired part.

Step 5: Cooling and Solidification

After injection, the mold is cooled to allow the molten material to solidify. Cooling is a critical step, as it determines the part’s quality and structural integrity. The cooling process can be controlled through various means, such as cooling channels within the mold and precise temperature regulation.

Step 6: Ejection

Once the plastic has solidified, the mold opens, and the ejector mechanism pushes the finished part out of the mold cavity. Ejection marks, also known as witness marks, may be present on the part’s surface, but they can often be eliminated or minimized during post-processing.

Step 7: Quality Control and Inspection

Every injection molded part undergoes a thorough quality control inspection to ensure it meets the specified tolerances and quality standards. This step includes measurements, visual inspections, and functional tests to identify any defects or deviations from the design.

Step 8: Post-Processing and Finishing

Depending on the part’s requirements, post-processing and finishing may be necessary. This can include trimming excess material, removing ejection marks, and adding secondary operations like assembly, painting, or texturing to achieve the desired final appearance and functionality.

Step 9: Packaging and Distribution

Once the injection molded parts have passed quality control and any necessary post-processing, they are ready for packaging and distribution. Parts are carefully packed to prevent damage during transit and are prepared for delivery to customers or assembly lines.

Conclusion

The injection molding process is a meticulous and well-orchestrated sequence of steps that transforms raw materials into a wide range of plastic parts and components. From mold design to quality control and distribution, each stage demands precision and expertise to ensure the final products meet the desired specifications. Understanding this process provides valuable insights into the world of manufacturing and the creation of countless everyday items.