Sand casting is the oldest casting technique in the market, as it can be traced back to as early as 1000 B.C. This method led to the birth of other casting techniques like metal casting. In sand casting, sand is used to create the mold where the molten metal is poured. Despite the development of several other casting techniques, sand casting remains to be the most widely used and the most versatile method in existence. The process of sand casting starts with the design then the creation of the sand casting mold. This post will focus on the creation of sand casting molds.

How to create a sand casting mold

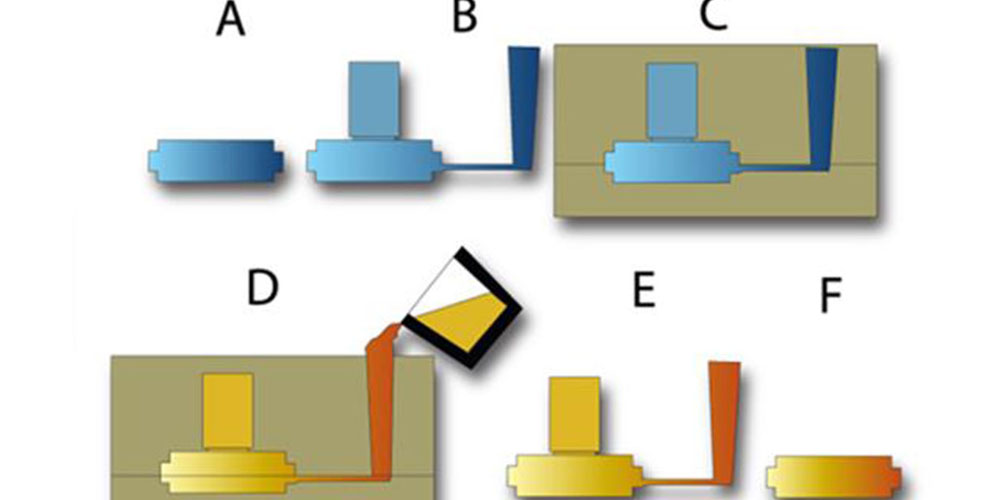

Creating the mold is one of the most critical steps of the sand casting process. For the sand casting mold to be made, you need to begin by making the foundry pattern known as the design. Once the pattern is completed, you can start creating the mold.

You will need refractory material for the process. The refractory material needs to be stable at high temperatures. It must also be strong enough to handle the weight of the molten material during the part formation. It must also be brittle enough to be broken away from the solidified metal or material after cooling the cast. The material, which in this case is sand, is formed around the pattern. In sand casting, varieties of sand can be used. In most cases, the sand used is combined with other materials like a bonding agent. Doing this helps strengthen the sand so that it can withstand the pouring process without getting displaced.

The sand casting mold is usually made in two pieces. The top piece is known as the cope, while the bottom or second piece is the drag. This allows for the separation and removal of the pattern. In some instances, the mold can include cores. This is essential in areas where the final product features internal passageways.

Creating the sand casting mold is as easy as firmly packing sand into each pattern. The firmness is meant to prevent any loose sand. This can be done by hand or machine. After the sand filled into the pattern, the patterns are removed. Doing this leaves the exterior contours in the sand. These are the parts where channels and connections known as gates or runners are created. These parts are essential for accuracy in the sand casting process. They allow the metal to enter all corners of the mold.

After the sand casting mold is created, a refractory coating can be added to it. Doing this helps create a better surface finish. It also protects the mold from the turbulence caused by the molten metal when it is being poured. The two halves are placed together before the molten metal is poured into the sand casting mold. Doing this creates a cavity in the shape of the desired final part.

Final word

It is worth mentioning that the mold can also be created via the machining of the desired shaped cavity directly onto the sand. This is a popular technique because it allows you to manage and implement changes to the design effortlessly.