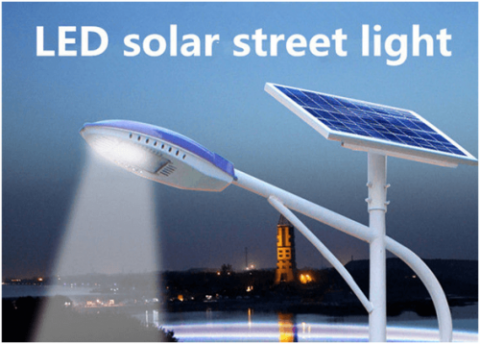

Whenever you see a Commercial street light, functioning without any wired connection underground or above ground to a power source, then you should know that it is a commercial Solar Powered Street Light. Commercial Solar Powered Street Lights are raised street lights that are powered through solar panels mounted on the lighting pole. The solar panels transmit energy to a rechargeable battery which powers an installed LED Lamp or Fluorescent. The Commercial Solar Powered Street Light are installed along walkways, in compounds and along roads for illumination when it gets dark. And peak sun hours is one of important factors to see whether your place is suitable to use solar lights or not. For the installation of a Commercial Solar Powered Light, you are just a click away in contacting enkonn-solar.com for the best of solar light.

Components of a Commercial Solar Powered Street Light

- The Solar Photo Voltaic Panel: this is one of the most crucial components of a Commercial Solar Powered street light because, it is the board that receives the solar energy and converts it to electricity. The solar panel constitutes two types which are: The Mono-Crystalline and The Poly-Crystalline.

- The Lighting Component: this component constitutes of different types of lamps like the Compact Fluorescent Lamps (CFL), High Pressure Sodium (HPS) Lamps, Low Pressure Sodium (LPS) Lamps, and the Light Emitting Diodes (LED). This component brings about the end product of the processing of the solar energy being absorbed by the Solar Panel.

- The Rechargeable Battery: the rechargeable battery is the device that stores the solar energy converted by the Solar Panel. The Rechargeable battery powers the Lighting component in order to give out visible light energy required.

- The Pole: this is the component that raises all the other devices above the ground. The solar photo voltaic panel is mounted at the top of the pole while the lighting component (LED) is attached to the near top in a way that the visible light will be facing the ground. The battery and other devices will be housed in a box-like material that will be attached also to the body of the pole.

How it works.

Steps that the Commercial Solar Powered street light takes before it starts giving out light

- The first thing that happens is the absorption of solar(sun) energy by the solar panel, then the solar energy will be converted into electrons by the solar panel and the electrons will be sent as charge energy to the battery.

- During the charging of the battery, the charge control device monitors the charging of the battery in order for the battery not to overcharge. This same device controls the amount of energy that will be sent to the inverter for the powering of the LED Lamp.

- Once the solar panel stops receiving radiation from the sun, there is a device called “photocell” (for solar street lights that on and off automatically) that will sense the absence of solar energy and the presence of darkness thereby switching on the LED Lamp when its time.

Disadvantages of Commercial Solar Powered Street light

- Higher theft risk.

- Snow, dust, moisture or the three combined can reduce or stop energy production when covering the photo voltaic panel.

- The replacing of Rechargeable batteries over the time of functioning of the light fixtures can increase the cost of the light.

The Advantages of Commercial Solar Powered Street Light

- Commercial Solar Powered Street light doesn’t require Utility Grid before functioning.

- A very low operational and maintenance cost is required for using a Commercial Solar Powered Street light.

- Low or No accidental risk is associated with the usage of Commercial Solar Powered Street light.

- Transportation of the Commercial Solar powered Street light component can be done separately thereby easing stress of transporting when going to remote areas.

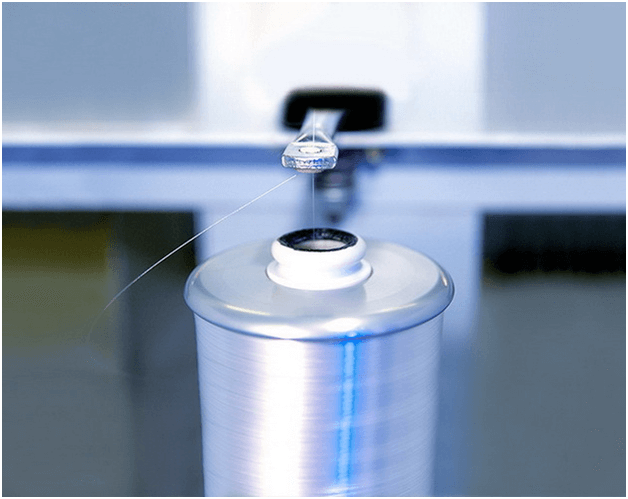

LED bulbs do not have a filament; they emit light via the movement of electrodes in a semi-conductor device. The diodes emit light of a specified color without the use of color filters.

LED bulbs do not have a filament; they emit light via the movement of electrodes in a semi-conductor device. The diodes emit light of a specified color without the use of color filters. The bulb’s brightness depends on the gas that is used. For instance, bulbs with standard brightness use argon while those bulbs with higher brightness use pure neon gas.

The bulb’s brightness depends on the gas that is used. For instance, bulbs with standard brightness use argon while those bulbs with higher brightness use pure neon gas.