The car industry in Germany is one of the biggest businesses on the planet, with a work power of more than 747,000 working in the business

Being home to the cutting edge auto, the German car industry is viewed as the most aggressive and creative in the world and has the third most astounding auto generation in the world and fourth most astounding aggregate engine vehicle generation. With a yearly yield near six million and a 35.6% offer of the European Association.

German-composed autos won in the European Auto of the Year, the Worldwide Auto of the Yearend the World Auto of the Year yearly honors the most circumstances among all nations. The Volkswagen Scarab and Porsche 911 acquired the fourth and fifth positions in the Auto of the Century award.

Early history of Automotive Industry in Germany.

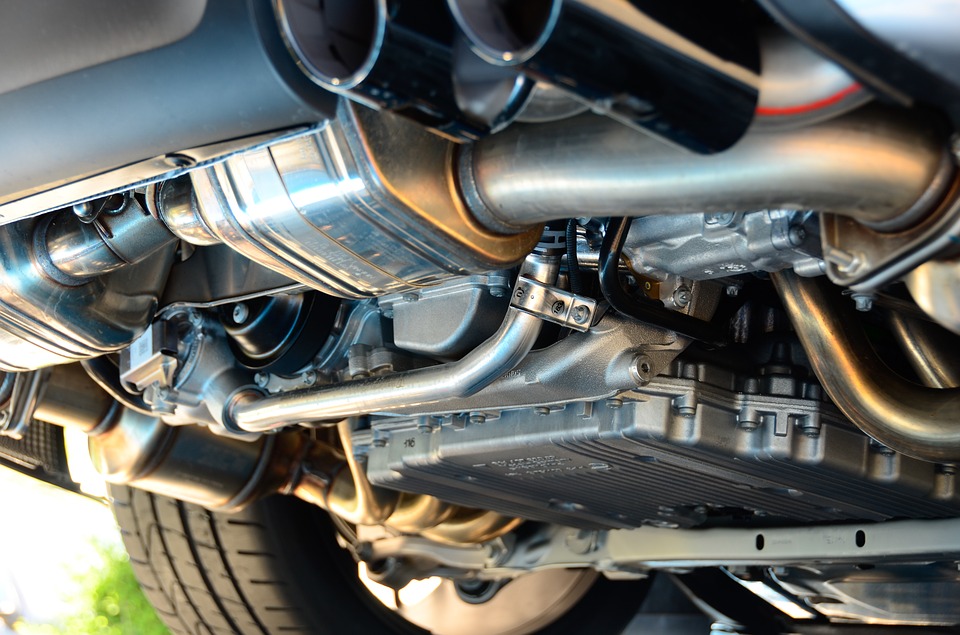

Germany was constantly motivated by the English car industry in the late 1860s and as engine, auto pioneers Karl Benz and Nikolaus Otto created four-stroke inner ignition motors in the late 1870s, with Benz fitting his plan to a mentor in 1887, which prompted the advanced engine auto. By 1901, Germany was delivering around 900 autos a year.

In 1926, Daimler-Benz was shaped from the forerunner organizationsof Karl Benz and Gottlieb Daimler and created autos under the marque of Mercedes-Benz. In 1916 BMW was establi shed, yet did not begin auto creation until 1928.

American financial analyst Robert A. Brady broadly reported the justification development that formed German industry in the 1920s, and in spite of the fact that his general model of the development connected to the car business, the area was in weakness in the later years of the Weimar Republic.

Germany’s moderate advancement of the business left the market open for significant American automobile producers, for example, General Engines who assumed control German organization Opel in 1929, and the Portage Engine Organization, which kept up the fruitful German backup Passage Werke, starting in 1925.

After war period.

Before the finish of World War II, the majority of the auto processing plants had been crushed or seriously harmed. Germany required obligation alleviation. The London Concession to German outside Obligations of 1953 gave that reimbursements were just due while West Germany ran an exchange overflow, and that reimbursements were restricted to 3% of fare income.

This gave Germany’s lenders a capable motivating force to import German products, helping recreation of the Auto Industry. Moreover, the eastern piece of Germany was under control of the Soviet Association, which destroyed a great part of the hardware that was left and sent it back to the Soviet Association as war reparations. A few producers, for example, Maybach and Adler began up once more, yet did not keep making traveler autos. The Volkswagen creation office in Wolfsburg kept making the Volkswagen Creepy crawly in 1945, an auto that it had expected to make before the war with the exception of that the industrial facility was changed over to military truck generation amid the war. By 1955, VW had made one million Volkswagen Scarabs, and by 1965 had fabricated 10 million, as it picked up fame on trade showcases and on the home market.

Other car manufacturers modified their plants and gradually continued generation, with beginning models generally in view of pre-war outlines. Mercedes-Benz continued generation in 1946 with the pre-war outlined 170 arrangement.

Passage combined its German and English activities in 1967, with the aim of creating indistinguishable autos at its German and English production lines. Portage had additionally opened a plant at Genk, Belgium, in 1963. In 1976, it likewise opened a processing plant in Valencia, Spain, where creation of the new Party supermini was concentrated.

The Escort, propelled in 1967, was the main new Portage to be created at both the German and English industrial facilities. Toward the start of 1969, Passage propelled another wearing roadster, the Capri, which like the Escort was created all through Europe.

The Taunus of 1970 made utilization of an indistinguishable fundamental plan from the English Cortina MK3, yet had somewhat unique outside styling, in spite of the fact that those styling contrasts were resolved with the dispatch of the 1976 Taunus. Portage’s new leader show, the Granada, was worked in England, Germany, and Spain from the earliest starting point of 1972, albeit English creation was pulled back following a couple of years.

The Automotive Industry in the 1970s

This area does not refer to any sources. If you do not mind help, enhance this area by adding references to solid sources. Unsourced material might be tested and expelled. Volkswagen was looked by major monetary challenges in the mid-1970s; with its maturing Creepy crawly, as yet offering firmly everywhere throughout the world, yet its more up to date models had been less effective.

Be that as it may, the organization at that point delighted in a restoration with the entry of the well-known Passat in 1973, Golf in 1974 and Polo in 1975 – these autos highlighted the new front-wheel drive hatchback format which was getting a charge out of an ascent in prevalence crosswise over Europe after first being licensed by Renault of France with the R16 in 1965.

The Polo was Volkswagen’s new passage level model, and was pointed straightforwardly at present day little hatchbacks like the Fiat 127 and Renault 5. The mid-run Golf was viewed as the auto to in the end supplant the Scarab, and was effortlessly the main prominent hatchback of this size in Europe, prompting most driving carmakers having a comparative measured hatchback by the mid-1980s.

Generation of the Bug completed in Germany in 1978, in spite of the fact that it kept on being created in Mexico and Brazil until the point that 2003, with few models being foreign to Germany and whatever is left of Europe amid its last 25 years. The Passat was promoted as a further developed contrasting option to conventional bigger cantina autos like the Passage Taunus/Cortina, Opel Ascona; sold in England from 1975 as the Vauxhall Unceremonious and the Renault 12.

5.Lockheed Constellation. The Connie is known for being the first pressurized airliner in widespread use. Built between 1943 and 1958, the Constellation ushered in an era of affordable and comfortable air travel.

5.Lockheed Constellation. The Connie is known for being the first pressurized airliner in widespread use. Built between 1943 and 1958, the Constellation ushered in an era of affordable and comfortable air travel.